Microtome blades are generally made of stainless steel which is machined to produce an edge and tip geometry that have proven over a time to result in good cutting performance. A coating is imparted on the steel blade to improved the cutting performance & life of the blade.

Edge sharpeners is actually the degree to which a cutting blade can be machined to a precise & distinct point. This point must be maintained in a straight line across the full length of the blade edge. Poor edge sharpness causes high compression & sample slide separation.

CUTTING ANGLES

A small knife angle will result in decreased stress on cutting edge of the knife provided optimal clearance on angle is maintained. The clearance angle in the most important angle typically maintained between 2°-8°. Too large clearance angle will cause scraping or chippingof sections instead of cutting.

SPECIAL COATING

With a special coating for the blades it performs without scratches on the specimens for long. With Plasma technologies that improve sharpness and durability of the blades considerablyMORE NO. OF BLOCKS/BLADES

Average number of block per a blade with 3 micron sectioning: 50~60 blocks for the pathological specimens, 35~40 blocks for the anatomical specimensCUT HARD & COMPLEX TISSUES

MEDIMEAS enables thin sectioning with hard tissues. It performs well for the myoma of the uterus, the prostate, the mammary gland, the thyroid gland, the bronchial bones, etc.NO COMPRESSION

MEDIMEAS performs to maintain the original shape of specimen. With less friction at sectioning the paraffin sections are maintained almost same size of blocks.NO CURLING

No curling of sections. Thus it helps to attach the sections onto the slide.

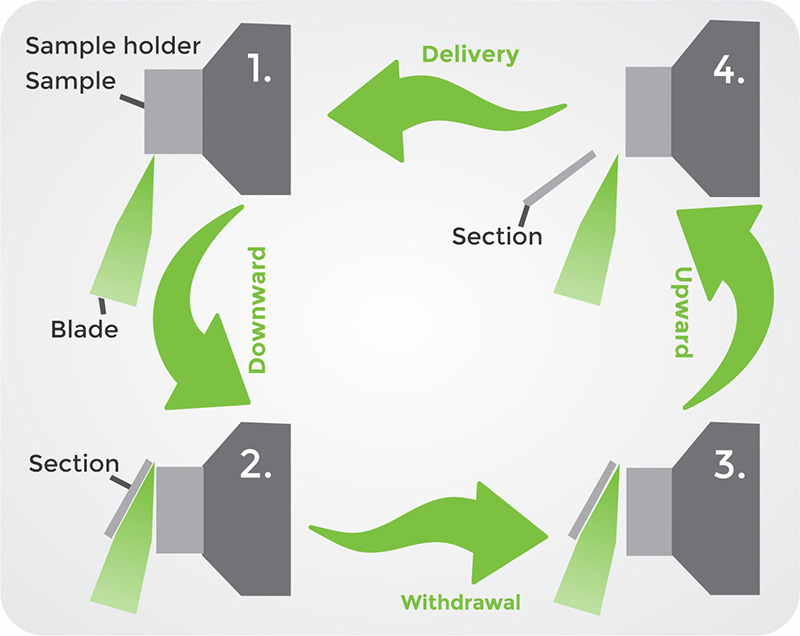

CUTTING CYCLE

The blades are mounting on a blade holder and is used to cut the specimen block. The blade geometry is typical with a tip having a cutting edge. Typical thickness of blade is 0.25mm. The blade has a straight portion and some bevel portions forming the cutting edge. During the cutting actions the blade edge cuts through the tissue sample and the tip contacts the tissue slide on one side & tissue block on other. Fig shows the direction of movement of the tissue block with respect to the microtome blade.

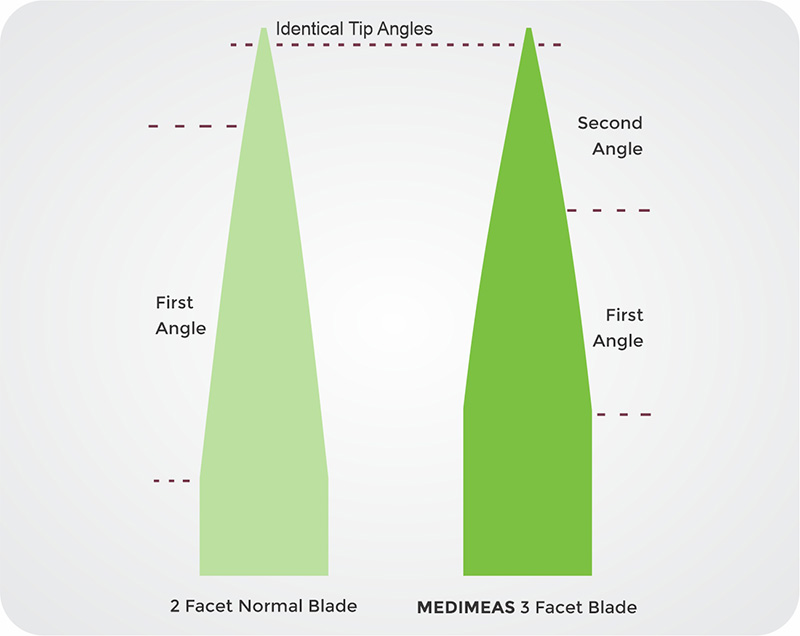

BLADE FACETS

Blade edges must not only be sharp, but sharp at the right angle and made with the right number of facets. Precision-ground three-facet blades balance sharpness and durability, cut with greater precision and are ideal for intricate cuts. The more facets, the finer the cut. But many tissues are simply too demanding for single-bevel blades. They require the toughness of a two-facet or sharpness of a three-facet edge. That is where MEDIMEAS 3 facet blade with broader base stands out.

EXCELLENT CUT FEEL

The feel that the histologist has for the fineness and ease of cut as he/she operates the microtome. Cutfeel is dependant on the hardness of the edge and the edge tip smoothness. The blade edges are hardened by a special process and a plasma coating ensures its smoothness giving superb feel while cut as there is no function between the blade & section.Histologist should feel effortless & smooth while cutting the sections, the blade should move through the specimen block without any friction which is dependant on characteristics of blade & block which are sliding against each other.

ZEROCOMPRESSION OF SECTIONS

The distance a specimen sample slice is compressed from the original dimension by the cutting action. Compression is a result friction between the blade & the tissue and also the thickness. Optimal blade edge thickness with smooth edges ensure no compression. Also hardness of the blade edge ensure that the tissue size in the block & on the slide is same.Perfectly designed and smooth edges ensures that compression do not occurs in the cut sections. These imperfections cause marks on the tissue specimens during cutting.

OUTSTANDINGSLIDE CLARITY

The clarity, or the absence of defects i.e. striations, that a specimen slide has when mounted and stained on a glass slide used in microscopic examination. Slide clarity is also a function of hardness of the blade and the surface finish of the blade edge. The coating not only smoothens the edges but also gives excellent surface finish so that you get excellent slide clarity.

THE BIG QUESTION | High Profile VS Low Profile

| Angle | Length mm | Edge width (mm) | Thickness mm | |

|---|---|---|---|---|

| LOW PROFILE | 35 | 80 | 8 | 0.25 |

| HIGH PROFILE | 35 | 80 | 14 | 0.32 |

- Microtome blade: the thinner blade allows for a shorter taper and a sharper angle.

- All other things being equal, a thinner blade will be sharper and a thicker will be more durable.

- Assuming equally good holders, a low profile blade, is more likely to shudder or otherwise move when challenged by a tough specimen, than is a high profile knife.

- Not surprisingly a lot of people chose thicker, high profiles blades for cryostat sectioning and thinner low profile blades for sectioning at 3 or less micrometers.

Are you facing any of the following difficulties:

Crooked or Uneven Ribbons

Compressed Wrinkled or Jammed Sections

Crumbling or tearing of sections

Split Ribbons on Lengthwise

Lifting of Sections or Ribbon on up stroke

Thick and Thin sections

Chattering

Venetian Blinds & Scratches

1

To maximize the sharpness of your knife’s edge, use an old knife to trim your first block, or use the extreme end of your new or reconditioned knife.

2 Continuously remove the paraffin, or other embedding medium, on the front and back of your knife to maximise your cutting performance

3 Depending on the texture of the tissue you have been cutting, you may be able to use the other side of your knife for extended use.

4 Setting your knife at the proper clearance angle will obviously not only enhance your output but it will also extend the life of your knife’s edge.

5 Maintain a sharp edge on your knife. Even the most highly skilled technologies cannot overcome the handicaps created from using a dull or bruised knife.

6 Based on the facet/bevel angle created in our reconditioning process, we recommend a clearance angle between 6° and 8°.

7 When your knife is reaching its dimensional maturity, i.e. the width of the knife’s surface is less than 7/8 of an inch, proper knife stability is difficult to achieve in the holder. Placing a hexagonal pencil at the base of the knife within the holder will act as a filler and provides it with the support required.

2 Continuously remove the paraffin, or other embedding medium, on the front and back of your knife to maximise your cutting performance

3 Depending on the texture of the tissue you have been cutting, you may be able to use the other side of your knife for extended use.

4 Setting your knife at the proper clearance angle will obviously not only enhance your output but it will also extend the life of your knife’s edge.

5 Maintain a sharp edge on your knife. Even the most highly skilled technologies cannot overcome the handicaps created from using a dull or bruised knife.

6 Based on the facet/bevel angle created in our reconditioning process, we recommend a clearance angle between 6° and 8°.

7 When your knife is reaching its dimensional maturity, i.e. the width of the knife’s surface is less than 7/8 of an inch, proper knife stability is difficult to achieve in the holder. Placing a hexagonal pencil at the base of the knife within the holder will act as a filler and provides it with the support required.

Download our Microtome Blade Trouble Shooting Guide

For more information about MRM-RM Manual Rotary Microtome , prices and delivery times, write to us at contact@medimeas.com or fill in the contact form.[fc id='1' type='popup' button_color='#ee4444' font_color='white' font_size='22px']Download Now[/fc]