Ensure excellent tissue processing quality as tissue are processed in a fully enclosed environment and under Vacuum.

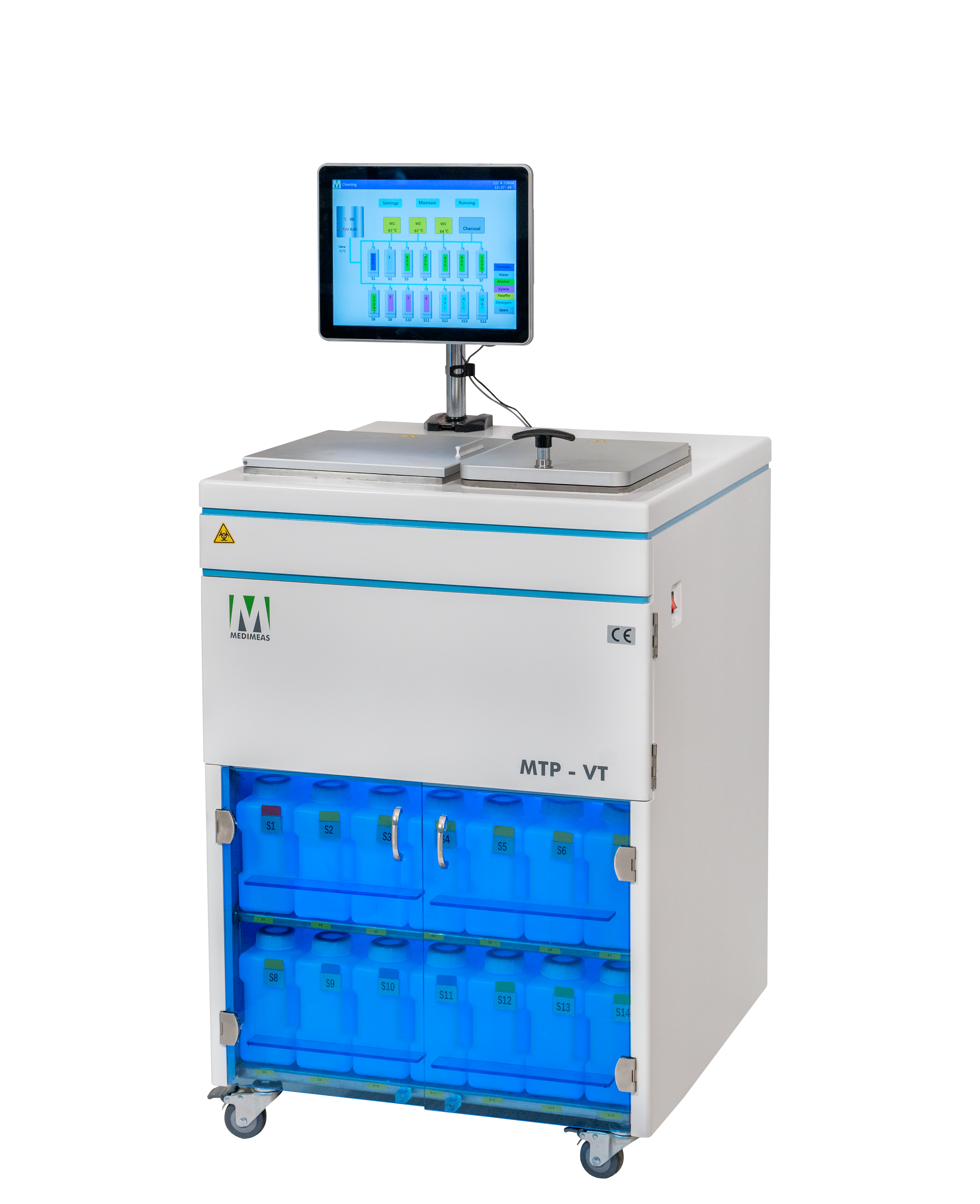

Medimeas Vacuum tissue processor is designed for excellent performance and reliability with feature like Stirrer in retort for better infiltration of tissue sample and multi programmable memory gives flexibility to operator to select different programs depending on tissue type.

Floor standing tissue processor processing upto 300 cassettes

User can select cycle with vacuum

Metal tissue basket specially design to avoid sticking of basket

distinct fill levels with sensor in processing chamber to shorten processing time

Fully automatic and programmable reagent management system

Comprehensive monitoring & full process control

Inbuilt password protected area

Ability to interface with LIS system

Reagent storage cabinet is built to enhance safety standard and is vented through two additional filters for further fume control

Systematic logging and reporting of quality control data, event records and program inform in the quoted model

Specimen safety and protection is accomplished by in built battery back up of 40 minutes in hour

Auto cleaning cycle, efficient paraffin wax cleaning system to extract solvent contaminants to increase wax life.

Colour touch screen LCD display of cycles, reagents levels, date & time user friendly softwares

Continuous agitation circulates reagents freely around specimens

Alarm system, password protected, instrument supervisor mode

Optional barcode reader

Micro-processor based auto memorization and recovery.

Automatic in- process reagent rotation no manual handling of reagents

Low reagent alarm system. Remote alarm to signal possible problems and reagent change.

Warning alarm for trouble free operation

Remote fill & drain system

Compatible with standard reagent system

Disposable wax tray system makes wax replacement clean and simple

Automatic/Manual functioning mode.

Protection from overheating and excessive vacuum and pressure

Vacuum & fume control system, running rapid biopsy protocol

Possibility of interrupting an automatic process for reloading or removing cassettes for application before the end of a run

Retort filling time selectable

Filling time user selectable from 4 to 7 mins

Inbuilt reagent level sensor to deduct reagent level during processing

Suitable tissue flotation water bath will be provided

Machine pre-test after starting the program to confirm that all lines and valves are un-blocked working fine

Processing retort volume tissue penetration and processing

Machine have inability cleaning cycle after ending program to clean the wax from retort and pipes to increase reagent

| Technical Specification | |

|---|---|

| PROCESSING RETORT | |

| Maximum Capacity | 300/400 cassettes |

| Retort Material | Stainless Steel |

| Processing Retort Volume | 5 litres |

| Temperature(Parafin) | 40 to 70oC |

| Temperature (Cleansing Reagent) | 40-67oC |

| Temperature(Reagent) | 35oC to 60oC |

| Temperature Accuracy | ±10oC |

| Vacuum | -70kPa |

| Pressure | +35kPa |

| Time Selectable Range of each stn. | 0 to 99 hrs, 59 mins |

| PARAFFIN BATHS | |

| No. of Baths | 3 |

| Volume | 4 litres each |

| Average Melting Time | 3hrs approx |

| REAGENT BOTTLES | |

| No. of Bottles | 10 |

| Bottle Volume | 5 litres each |

| CLEANING BOTTLES | |

| No. of Bottles | 3 |

| Bottle Volume | 4 litres each |

| GENERAL | |

| Delay Time | Upto 7 days |

| Voltage | 220V @ 50-60Hz |

| Overall Dimensions | 620x680x1280mm |